The ZD-FJ08C paper bag machine produces much smaller paper bags without handles than the ZD-QFL18/21B model. Equipped with Siemens PLC system, the paper bag equipment takes rolls of paper and turns them into individual paper bags to use as food bags, shopping bags, and grocery bags.

Technical Specifications

| Model | |

| Paper Roll Width | 290~630mm |

| Max. Paper Roll Diameter | Ф1200mm |

| Paperboard Core Diameter | Ф76mm (3’’) |

| Paper Thickness | 45~130g/m2 |

| Tube Length | 190~370mm |

| Bag Body Width | 80~200mm |

| Bag Bottom Size | 50~100mm |

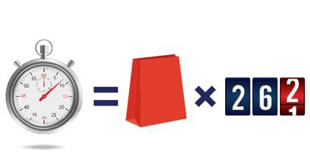

| Max. Production Speed | 260bags/min |

| Total Power | 13.5kw |

| Total Weight | Approx. 6000kg |

| Overall Dimension | L8500mm×W3000mm×H1600mm |

Model ZD-FJ08C paper bag machine provides a fast way to make small square bottom paper bags. With one unit of equipment, operators can perform a series of operations, including paper feeding, body panel forming and cutting, and adding the square bottom. The high level of automation keeps labor costs low.

Thanks to the photo eye, bag length errors can be corrected on the fly during the cutting process. A compact, space-saving footprint gives your factory a tidy image, while producing small paper bags with a professional look. When your bag quality matters, Fangbang Machinery is the trusted Chinese paper bag making machine provider you can rely on!

Sample

Whether it is a food bag, gift bag or a kraft paper bag, Fangbang

roll-fed square bottom paper bag machine can handle them all. Like our

ZD-FP14B/18B models, the machine featured on this page can not make

paper handles.

Features

Close-up Views of Paper Bag Making Machine