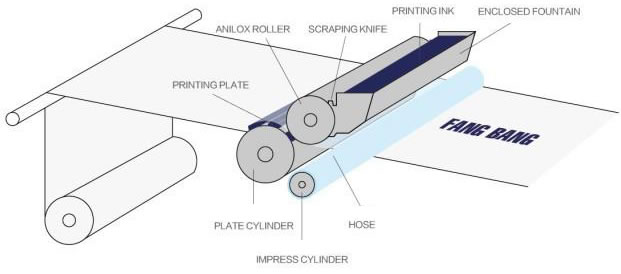

Not just known as a trusted Chinese bag machine manufacturer, Fangbang also takes great pride in the part it has played in the improvement of flexo printing technology. Throughout Fangbang's fruitful history of innovation, the flexo printing machine has undergone two major improvements which brought the technique to where it is today.

Originally, Fangbang YT-1000C flexo printing machine uses photosensitive resin and rubber to construct the printing plate. Ink is fed to the plate roller via another roller called the anilox roll. As the plate roller rotates, the ink on the printing plate is transferred to the object being printed.

Technical Specifications

| Model Code | |||

| Paper Grammage | 60~400g/m2 | 60~400 g/m2 | 60~400 g/m2 |

| Max. Material Roll Width | 1020mm | 1320mm | 1520mm |

| Max. Print Width | 1000mm | 1300mm | 1500mm |

| Print Repeat Length | 360~1200mm | 360~1200mm | 360~1200mm |

| Max. Unwinding Diameter | ф1500mm | ф1500mm | ф1500mm |

| Max. Rewinding Diameter | ф1500mm | ф1500mm | ф1500mm |

| Gear Specification | 1/8cp | 1/8cp | 1/8cp |

| Max. Printing Speed | 150m/min | 150m/min | 150m/min |

| Guiding Roller Diameter | ф100mm | ф100mm | ф100mm |

| Main Motor Power | 11kw | 15kw | 18.5kw |

| Drying Mode | Hot air drying or infrared drying | ||

This flexographic printing process is great for a variety of reasons. For one thing, it works the fastest among other printing methods, due to the use of fast-drying ink. As an added convenience for machine operators, the advanced PLC system maintains automatic control of the entire color printing process, from unwinding and tension adjustment, to feeding, printing, and drying, to rewinding. Other desirable features include the deviation correction, tension control, roll change pre-warning, emergency stop (in the event of roll breakage), and dust removal.

Both YT-1300C and YT-1500C flexo printing machine can print on wider paper than the comparable YT-1000C model.

Sample

Take a look at these colorful texts, logos, and graphics printed on

customer’s paper bags, carton boxes, and paper cups. Get a feel for why

so many clients have relied on Fangbang flexo printing machine for

eye-catching prints.

Features

1. Flexo printing uses the anilox roll to produce high quality results rapidly.

2. Ability to print on a wide range of materials from plastics to corrugated paperboards.

3. Allows the addition of print units, otherwise known as stations, in

order to create different tints and shades. Each print unit is printing

a single color.

4. Low costs associated with producing flexograhpic plates and

printing press setup. Scrap rate is low. Brings 30% to 50% cost savings

compared to gravure printing.

Close-up Views