Automatic case maker adopts automatic paper feeding system and automatic cardboard positioning device; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make perfect book covers, notebook covers, calendars, hanging calendars, files and irregular cases etc.

Features

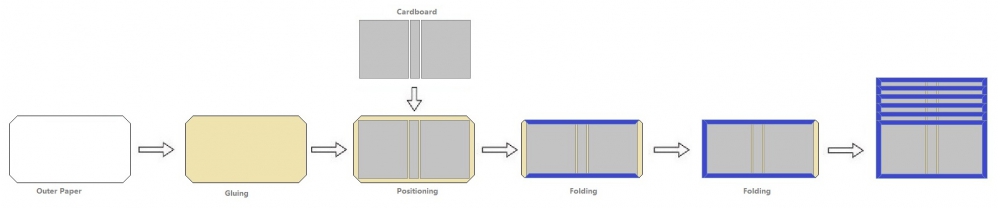

1. Automatically delivery and gluing for paper

2. Hot melting glue circulation system

3. Automatically delivering, positioning and spotting for cardboards with high accuracy positioning system

4. Automatically folding and forming case four-edge.(Available to make Irregular shape cases)

5. With friendly HMI, all troubles will be displayed on the computer.

6. Integrated cover is designed according to the European CE Standards, featuring in safety and humanity.

7. Optional device: glue viscosity meter

Production Flow

Product Sample

Main Technical Parameters

Model | CM540A | |

1 | Case size(A×B) | MIN: 100×200mm MAX: 540×1000mm |

2 | Paper size(A×B) | MIN: 90×190mm MAX: 570×1030mm |

3 | Paper thickness | 100~300g/m2 |

4 | Cardboard thickness(T) | 1~3mm |

5 | Min. spine size (S) | 10mm |

6 | Folded paper size(R) | 10~18mm |

7 | Max. quantity of cardboard | 6pieces |

8 | Precision | ±0.1mm |

9 | Production speed | ≦38sheets/min |

10 | Motor Power | 12kw/380v 3phase |

11 | Electric Heating Power | 10kw |

11 | Air supply | 30L/min 0.6MPa |

12 | Machine weight | 3500kg |

13 | Machine dimension (L×W×H) | L9000×W2300×H1700mm |

Remark

1. The Max. and Min. sizes of cases are subjected to the size and the quality of the paper.

2. The speed depends on the size of cases.

3. Work shift time for a skillful operator from one product to another: within 30min

4. Air compressor isn’t included.